Effective inventory management is crucial for businesses to stay competitive and profitable. With inventory management platforms, companies can track their stock levels in real-time, streamline supply chain operations, and make informed decisions. These platforms provide a centralized system to monitor inventory across multiple locations, optimize stock levels, and automate routine tasks. By implementing an inventory management platform, businesses can reduce stockouts, overstocking, and unnecessary costs, ultimately leading to improved efficiency and increased customer satisfaction, making it an essential tool for any business looking to thrive in today’s fast-paced market. Real-time control is now possible.

To manage inventory effectively, it’s crucial to have the right tools in place. One such tool is an inventory management platform. This is a system that helps businesses keep track of their stock levels, monitor inventory movement, and make informed decisions about production and ordering.

What is Inventory Management?

Inventory management involves the processes and systems used to manage and control inventory levels, including ordering, storing, and stocking products. Effective inventory management is critical for businesses to ensure they have the right products in stock to meet customer demand, while also avoiding overstocking and waste.

Benefits of Inventory Management Platforms

Using an inventory management platform can have numerous benefits for businesses. These include real-time tracking, automated reporting, and optimized stock levels. By having access to accurate and up-to-date inventory data, businesses can make informed decisions about their operations and improve their overall efficiency.

Key Features of Inventory Management Platforms

When choosing an inventory management platform, there are several key features to consider. These include barcode scanning, inventory tracking, and reporting and analytics. The platform should also be able to integrate with other systems, such as accounting and e-commerce platforms.

Choosing the Right Inventory Management Platform

With so many inventory management platforms available, choosing the right one can be a challenge. Businesses should consider their specific needs and requirements, including the size of their inventory, the number of locations, and the level of complexity. They should also look for a platform that is user-friendly, scalable, and secure.

Best Practices for Inventory Management

To get the most out of an inventory management platform, businesses should follow best practices. These include regularly reviewing inventory levels, implementing a first-in, first-out (FIFO) system, and using data to inform decisions. By following these best practices, businesses can optimize their inventory management and improve their overall performance.

| Platform | Features | Pricing |

|---|---|---|

| Zoho Inventory | Barcode scanning, inventory tracking, reporting and analytics | Free trial, then $39-$99 per month |

| TradeGecko | Inventory management, order management, reporting and analytics | Free trial, then $39-$199 per month |

| Cin7 | Inventory management, order management, reporting and analytics | Custom pricing |

These inventory management platforms offer a range of features and pricing options to suit different business needs. By choosing the right platform and following best practices, businesses can optimize their inventory management and improve their overall performance. Effective inventory management is critical for businesses to ensure they have the right products in stock to meet customer demand, while also avoiding overstocking and waste. Real-time tracking and automated reporting are key features of inventory management platforms, allowing businesses to make informed decisions about their operations and improve their overall efficiency.

What is the real-time stock control system?

The real-time stock control system is a computerized system that allows businesses to track and manage their inventory levels in real-time, providing up-to-the-minute information on the quantity of products in stock. This system is designed to help businesses optimize their inventory management, reduce stockouts and overstocking, and improve their overall supply chain efficiency. With a real-time stock control system, businesses can make informed decisions about inventory levels, pricing, and production, enabling them to stay competitive in the market.

Benefits of Real-Time Stock Control System

The real-time stock control system offers several benefits to businesses, including improved inventory accuracy, reduced stockouts, and increased efficiency. Some of the key benefits include:

- Improved inventory accuracy, which enables businesses to make informed decisions about inventory levels and reduce errors.

- Reduced stockouts, which can lead to lost sales and revenue, by providing real-time information on inventory levels.

- Increased efficiency, which enables businesses to automate many inventory management tasks, freeing up staff to focus on other areas of the business.

Key Features of Real-Time Stock Control System

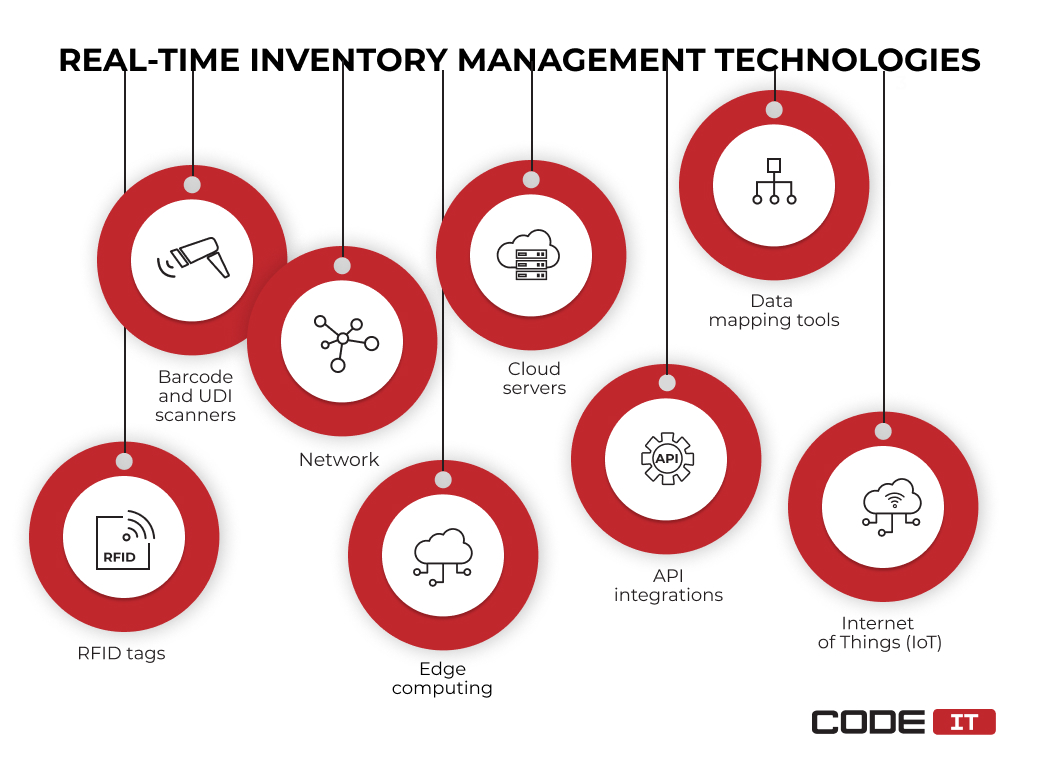

A real-time stock control system typically includes several key features, such as barcode scanning, radio-frequency identification (RFID), and automated reporting. These features enable businesses to track inventory levels in real-time, automate inventory management tasks, and make informed decisions about inventory levels. Some of the key features include:

- Barcode scanning, which enables businesses to quickly and accurately track inventory levels and movement.

- RFID, which enables businesses to track inventory levels and movement without the need for manual scanning.

- Automated reporting, which provides businesses with real-time information on inventory levels, enabling them to make informed decisions about inventory management.

Implementation of Real-Time Stock Control System

Implementing a real-time stock control system requires careful planning and execution, including needs assessment, system selection, and training and support. Businesses must assess their inventory management needs, select a system that meets those needs, and provide training and support to staff to ensure successful implementation. Some of the key steps involved in implementing a real-time stock control system include:

- Conducting a needs assessment, which involves identifying the business’s inventory management needs and requirements.

- System selection, which involves selecting a real-time stock control system that meets the business’s needs and requirements.

- Providing training and support, which enables staff to use the system effectively and make the most of its features and benefits.

How to track inventory in real-time?

![]()

To track inventory in real-time, it is essential to implement a robust inventory management system that utilizes advanced technologies such as barcode scanning, radio-frequency identification (RFID), and cloud-based software. This allows for accurate and up-to-date tracking of inventory levels, location, and movement. By using these technologies, businesses can optimize their inventory management processes, reduce errors, and improve overall efficiency.

Benefits of Real-Time Inventory Tracking

The benefits of real-time inventory tracking are numerous, and include increased visibility, improved accuracy, and enhanced decision-making capabilities. With real-time inventory tracking, businesses can:

- Monitor inventory levels and automatically generate low-stock alerts to prevent stockouts

- Track inventory movement and location to optimize storage and shipping processes

- Analyze inventory trends and patterns to inform purchasing and production decisions

This information can be used to streamline inventory management processes, reduce waste, and improve customer satisfaction.

Implementing a Real-Time Inventory Tracking System

Implementing a real-time inventory tracking system requires careful planning and execution. Businesses must first assess their current inventory management processes and identify areas for improvement. They must then select a suitable inventory management software and integrate it with existing systems, such as enterprise resource planning (ERP) and supply chain management (SCM) systems. Additionally, businesses must:

- Train employees on the new system to ensure a smooth transition

- Test the system to identify and resolve any technical issues

- Continuously monitor and evaluate the system to identify areas for improvement

This ensures that the system is functioning correctly and providing accurate and reliable data.

Best Practices for Real-Time Inventory Tracking

To get the most out of real-time inventory tracking, businesses must follow best practices, such as regularly updating inventory records, conducting physical inventory counts, and analyzing inventory trends and patterns. Additionally, businesses should:

- Use mobile devices to scan and track inventory in real-time

- Implement automated inventory reporting to streamline decision-making processes

- Integrate inventory tracking with other business systems, such as customer relationship management (CRM) and accounting systems

By following these best practices, businesses can maximize the benefits of real-time inventory tracking and achieve a competitive advantage in their industry.

What are the 4 types of inventory management system?

The four types of inventory management systems are designed to help businesses efficiently manage their inventory levels, track stock movements, and optimize storage capacities. These systems are essential for companies to minimize costs, maximize profits, and ensure customer satisfaction. The four types of inventory management systems are: Manual, Barcode, Radio Frequency Identification (RFID), and Cloud-based systems.

Benefits of Inventory Management Systems

The benefits of inventory management systems are numerous, including improved accuracy, increased efficiency, and enhanced visibility. Some of the key benefits include:

- Reduced stockouts and overstocking

- Improved inventory turnover and cash flow

- Enhanced supply chain management and demand forecasting

By implementing an effective inventory management system, businesses can streamline their operations, reduce waste, and improve their overall competitiveness.

Key Features of Inventory Management Systems

The key features of inventory management systems include real-time tracking, automated reporting, and customizable dashboards. Some of the other key features include:

- Serial number tracking and batch tracking

- Multi-location management and transfer management

- Vendor managed inventory and drop shipping

These features enable businesses to have complete control over their inventory, optimize their supply chain, and make informed decisions about their operations.

Best Practices for Inventory Management

The best practices for inventory management include regular inventory audits, cycle counting, and continuous improvement. Some of the other best practices include:

- Implementing a just-in-time inventory system

- Using data analytics to inform inventory decisions

- Providing training to employees on inventory management

By following these best practices, businesses can minimize errors, reduce costs, and improve customer satisfaction, ultimately leading to increased revenue and profitability.

How do I manage my inventory remotely?

To manage your inventory remotely, you need to have a centralized system that allows you to track and monitor your stock levels, shipments, and deliveries from anywhere. This can be achieved through the use of cloud-based inventory management software that provides real-time updates and automated tracking. With this system, you can easily access your inventory data, receive low-stock alerts, and make informed decisions to optimize your inventory levels.

Benefits of Remote Inventory Management

The benefits of remote inventory management include increased efficiency, reduced costs, and improved accuracy. By managing your inventory remotely, you can reduce the need for manual data entry, minimize inventory discrepancies, and improve your overall supply chain visibility. Some of the key advantages of remote inventory management include:

- Real-time tracking: Get instant updates on your inventory levels, shipments, and deliveries.

- Automated reporting: Generate reports on your inventory performance, including stock levels, sales trends, and profit margins.

- Customizable dashboards: Create personalized dashboards to track your key performance indicators and make data-driven decisions.

Tools and Technologies for Remote Inventory Management

There are various tools and technologies available to support remote inventory management, including inventory management software, mobile apps, and Internet of Things (IoT) devices. These tools enable you to track inventory movements, monitor stock levels, and receive alerts when inventory levels fall below a certain threshold. Some popular tools for remote inventory management include:

- Cloud-based inventory management software: Provides scalable, secure, and accessible inventory management solutions.

- Barcode scanning and RFID technology: Enables accurate tracking and efficient data collection.

- Mobile apps: Allows you to manage inventory on-the-go, receive notifications, and access real-time data.

Best Practices for Remote Inventory Management

To ensure effective remote inventory management, it’s essential to follow best practices, such as regularly updating inventory data, conducting cycle counts, and analyzing inventory trends. By following these best practices, you can optimize your inventory levels, reduce inventory costs, and improve your overall supply chain efficiency. Some key best practices for remote inventory management include:

- Set up automated alerts for low-stock levels and inventory discrepancies.

- Use data analytics to identify trends and optimize inventory levels.

- Implement security measures to protect your inventory data and prevent unauthorized access.

Frequently Asked Questions

What is an Inventory Management Platform?

An inventory management platform is a software solution designed to help businesses track and manage their inventory levels in real-time. This platform enables companies to monitor their stock levels, track orders, and automate various inventory-related tasks. With an inventory management platform, businesses can optimize their inventory levels, reduce overstocking and understocking, and improve their supply chain operations. By using real-time data and analytics, these platforms provide businesses with valuable insights into their inventory levels, enabling them to make informed decisions and drive growth.

How Does an Inventory Management Platform Work?

An inventory management platform works by integrating with a company’s existing systems, such as enterprise resource planning (ERP), e-commerce platforms, and point of sale (POS) systems. This integration enables the platform to collect and analyze data on inventory levels, orders, and sales. The platform then uses this data to provide real-time updates on inventory levels, track orders, and automate various inventory-related tasks, such as reordering and reporting. By using advanced algorithms and machine learning, these platforms can also predict demand and optimize inventory levels, helping businesses to reduce waste and improve efficiency.

What are the Benefits of Using an Inventory Management Platform?

The benefits of using an inventory management platform are numerous. For one, these platforms enable businesses to improve their inventory accuracy, which can help to reduce errors and increase customer satisfaction. Additionally, inventory management platforms can help businesses to optimize their inventory levels, which can reduce overstocking and understocking, and improve their cash flow. These platforms can also automate various inventory-related tasks, such as reordering and reporting, which can help to free up staff to focus on more strategic tasks. By using real-time data and analytics, inventory management platforms can also provide businesses with valuable insights into their inventory levels, enabling them to make informed decisions and drive growth.

How Can I Choose the Right Inventory Management Platform for My Business?

Choosing the right inventory management platform for your business can be a complex process. To start, you should identify your business needs and requirements, such as the size of your inventory, the number of locations, and the type of products you sell. You should also research different inventory management platforms and compare their features and pricing. Look for platforms that integrate with your existing systems, such as ERP and e-commerce platforms, and that provide real-time updates on inventory levels. It’s also important to read reviews and ask for references to get a sense of the platform’s reliability and support. By taking the time to evaluate your options and choose the right platform, you can improve your inventory management and drive growth for your business.